Service

WE SET GIANTS

INTO MOTION WITH A MOUSE

The best way to logistics success is a consistent networking of all processes.

Often hardly noticeable for customers we manage the supposedly minor things hand in hand and make sure projects run smoothly.

Whether route studies, packaging, storage, crane work/installation or laying foundations, project monitoring or the management of all interfaces – our services go far beyond pure haulage.

In terms of service we do everything except compromises.

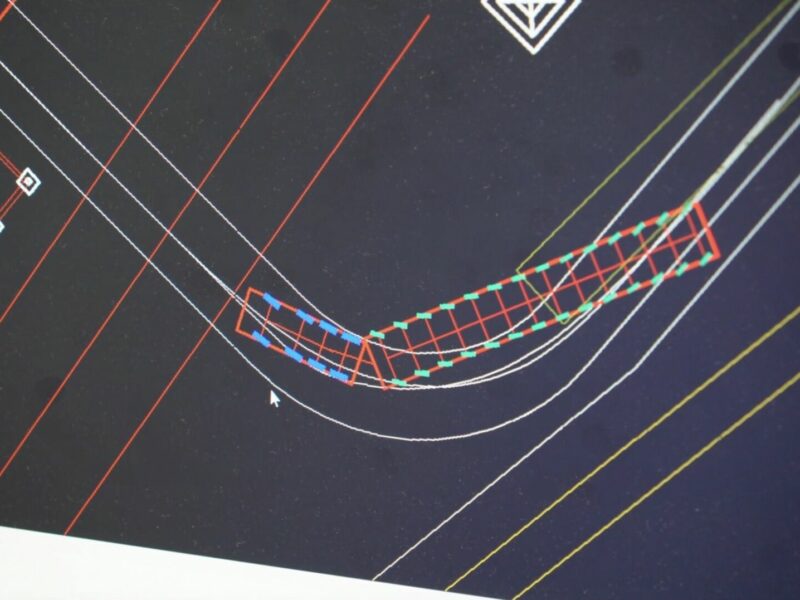

FEASIBILITY STUDIES

Taking the right decision to ensure optimal haulage is the task of our specialists.

In many cases we get involved as early as in the planning phase of the machine parts to be manufactured.

On-site inspections to check the space conditions or arrange for suitable transport routes and working areas are part of our daily routine.

Building on our staff’s expertise and the will to find the best solution for our customers we define the routing in form of protocols and check transport routes which includes a photo documentation.

The selection of suitable means of transport and determination of the transport procedures are the result of this advisory activity.

We also provide structural analyses both for the necessary loading aids and check-calculations of bridges to be crossed or arrange for the same at short notice.

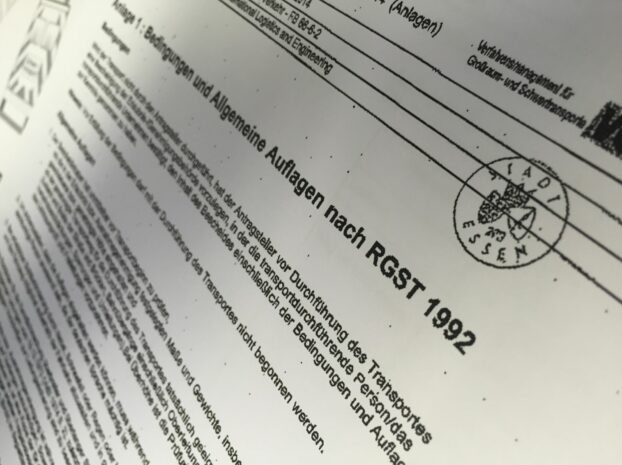

PERMITS

The procurement of all necessary permits (acc. to Road Traffic Regulations, Road Traffic Licencing Regulations, Working Hours Act etc.) belongs to our core competences.

Whether heavy or large-size cargo transports in Germany or elsewhere in Europe our approval service team deals with it from submitting applications through to the granting of permits.

Decades of experience and the contacts with official bodies, authorities and other institutions ensure a quick and reliable procurement of transport authorizations. Structural check-calculations of bridges to be crossed are arranged by us in a timely manner.

In coordination with all parties involved in the transport we take and control traffic management measures, such as putting up no stopping signs, cutting grass/bushes etc., removal of roundabouts, bridge superstructures and more.

TRANSPORT ESCORTS

For the protection of heavy and large-size cargo transports escort vehicles are required by the permit authorities called BF-3 or BF-4 vehicles.

BF–3 escort vehicles are additionally equipped with a variable traffic sign unit.

Our vehicles of latest design meet the quality requirements of the Federal Special Group for Heavy Loads and Crane Work (Bundesfachgruppe Schwertransport and Kranarbeiten – BSK) and are not only provided with all amenities for the personnel but also equipped with advanced communication systems including monitors and laptops.

The trained personnel possess not only the BSK authorization pass but is also qualified to remotely steer the transports to be escorted.

Regular in-house training adds to the know-how and maintains the quality standard.

HYDRAULIC WEIGHING

Unit loads of up to 800 tonnes have to be routinely lifted and moved by our erection crew using hydraulic jacks. At customer’s request we also determine the weights of the heavylift cargo. To this end we attach digital pressure gauges with an accuracy of +-0.5%.

This weigh scale is available as an alternative for weight measurements independent of any erection work. It is frequently used in absence of any other weighing facility, such as crane scale, floor scale.

Weighing of heavylift cargo by digital pressure gauges up to 1,000bar.

WHEEL LOAD SCALE

Portable wheel load scales of the Haenni WL103 type are used by the police to check the axle loads and gross weight of unloaded and loaded heavy-duty transporters.

With our own trained personnel and a larger number of own levelling mats we determine precise weights both for our own fleet and as a third party service

– Personnel (weighers) trained according to the Calibration Ordinance (Eichordnung)

– 32 levelling mats with a total length of 121m

– Weighing of our own vehicles

– Control results for police

– Weighing as a third-party service

WEIGHING

Our weighing system is ideal for weighing any type of heavy goods up to 600 t dead weight. Due to their wireless connection (via Bluetooth), they are particularly suitable for large projects with oversized dimensions, as the load cells (compression load cells) achieve a transmission range of 700 metres.

- Load capacity up to 1200 t

- Transmission range 700 metres

- Determination of total load

- Determination of the load of each individual measuring point

- Determination of centre of gravity

- 4 load cells (compression load cells)

- +- 0.02% deviation accuracy

- Asymmetrical arrangement of load cells possible

- dead weight 15.5 kg per cylinder

- fast and flexible assembly and disassembly

Thanks to the wireless positioning, work around the heavy goods to be weighed can continue without restrictions. In addition, the load cells accurately determine the weight and centre of gravity even with asymmetrical load points. In addition, the load can be determined at the individual measuring points.

Our weighing system is thus ideally suited for transport preparation (centre of gravity and deadweight determination) and execution, as we can use the system to ensure optimal positioning of the load on our vehicles.

SPECIAL EQUIPMENT

Our range of services is complemented by a multitude of special equipment.

It includes:

- 400 elephant feet with static load analysis:

- to lift and handle loads of up to 240 tonnes

- track plates

- excavator mats

- steel girders

- oil pans for transformer storage

TRANSPORT RACKS

Certain cargo often requires special loading aids to meet all requirements of a proper haulage.

The range may include simple timber beds through to weldments designed and tested by test engineers, as well as transport containers.

We develop and design optimal transport racks in line with the customer’s needs to protect the cargo and meet all requirements when it comes to securing the load.

We use:

-Saddles for the transport of pipes

-Tank supports

-Sloping platforms for loading weights of up to 90 tonnes

-Insulated steel hoods for the haulage of hot slabs at temperatures of up to 700°C

-Structures for a protected transport of wind power gear boxes.

INDUSTRIAL PACKAGING

As part of a customized overall logistics concept we offer the packaging of the goods to be transported.

In cooperation with our packaging partners the goods are packed according to HPE guidelines and customer specification. It applies both to packaging at the sender’s and at the seaport.

The trimodal connection of our business premises in Duisburg and Moers makes it possible to transport the packed goods by all modes of transport thus making sure that all requirements are met in a proper and efficient way.

Flexibility and reliability provide for an on-schedule implementation of the logistics processes.

FLY OVER BRIDGE

When heavy goods are transported it can often not be avoided to cross bridges the load-carrying capacity of which appears to be insufficient.

If after in-depth examination a bridge turns out to be too weak or rotten, we build bridges on bridges.

Our bridge crossing system is between 5m and 25m long at an axle load of up to 28 tonnes. It means that the bridge crossing system can carry a load of over 460 tonnes.

In combination with our vessel deck girders it is possible to bridge a distance of 36m.

PUSH AND PULL SKIDDING SYSTEM

For Installation and ground floor works we use an extremely low hydraulic skidding system of just 197mm in height.

This system makes it possible to move heavy units of up to 600 tonnes in transverse and longitudinal direction. It is used in particular where space is limited and service openings are narrow, and there is now way to use heavy-duty trucks.

2 x 32m skidding systems are available.

A mid-point loading of the skidding system beams of 100 tonnes per beam on 200mm is possible. The hydraulic cylinders can operate in two directions and thus both push and pull.

In connection with the turntable available the location of machines can be changed in different directions, i.e. longitudinally and transversely. As requested by the customer the heavy unit can be turned or shifted by any degree.

An optimal load distribution prevents new, coated industrial floors from being damaged.